Introduction to Fabric Heat Transfer Printing

Heat transfer printing lets you put custom designs on fabric. This amazing process has changed how we make custom clothes, home items, and promotional products in many different ways. The process starts by printing a design onto special paper. A heat press machine then uses heat and pressure to make the design stick to the fabric forever, creating bright and clear images that look great.

Heat transfer printing works on many types of fabric. The machine needs the right temperature and pressure to make the design stick properly, which takes practice to get right. This method is perfect for making both small and large amounts of items. Different techniques like dye sublimation have made the process even better over time.

Benefits and Applications

The process is very flexible. You can print on both light and dark fabrics by using different types of transfer paper and adjusting the settings on your heat press machine. Heat transfer printing creates designs that last through many washes. Most importantly, the finished products keep their bright colors and sharp details for a long time.

Understanding the Techniques of Fabric Heat Transfer Printing

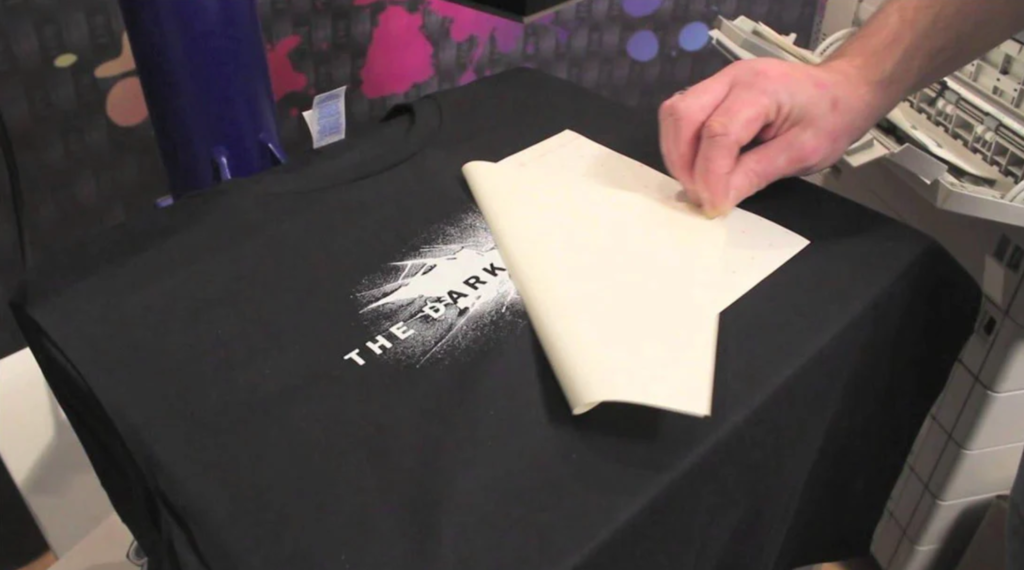

Heat transfer printing helps create designs on fabric using different methods. Each method comes with its own set of steps and special features that make it good for certain uses. People can print designs backward on special paper using normal printers in the basic method. The fabric needs to be heated first to get rid of any water in it. Then, using a heat press, the design gets transferred to the fabric in a process that works great for small orders and custom clothing. This method can print even tiny details clearly.

Different Printing Methods and Their Uses

Dye sublimation turns solid ink into gas with heat. The gas then soaks into synthetic fabrics, making prints that last long and feel smooth. The process works best on polyester clothes and sports gear. DTF printing uses special glue and powder to stick designs on any color fabric. It’s a newer method that offers more options than older ones.

Getting good results means paying attention to heat, pressure, and timing. These three things must be just right. Experience shows that picking the right method for each fabric type is key to making prints that look good. Understanding these basics helps people choose the right tools and make needed changes for the best results.

Best Practices and Tips for Perfect Transfer Printing

Getting your fabric prints just right takes careful work and attention. You need to follow a few simple steps to make sure everything turns out perfect. Start by warming up your fabric with a heat press at 350°F–375°F for a few seconds. This quick step gets rid of wrinkles and water that could mess up your print. A Teflon sheet or special heat pad helps spread out the pressure evenly when you’re pressing.

Setting Up Your Print

Make sure to flip your design before printing it onto the transfer paper. The right settings for heat, pressure, and time will change depending on what kind of fabric you’re using, so always check this first. If you see problems like colors running together or the design not sticking well, you probably need to adjust these settings. Keep your heat press clean and working properly.

Dark fabrics need special transfer paper made just for them. You might have to press a little harder when working with dark clothes. Do test prints before starting big projects, and keep your work area clean and organized. If you follow these steps carefully, your prints will stay bright and clear even after many washes.

Heat Transfer Printing on Fabric

Core Ideas and New Methods

Heat transfer printing on fabric has many ways to make cool designs. Getting good prints on dark or bumpy fabrics takes much more work and planning.

New methods like DTF printing and special dye printing give artists more choices to work with. These modern ways help make bright and lasting designs that stay on all kinds of fabrics.

Different fabrics need different settings when you print on them. Testing and practice show what works best for each kind of fabric.

Using new tools and keeping up with technology helps make sure your prints look their best. Your heat transfer projects can be amazing if you pay attention to these details.

Choosing the Right Tools and Materials for Fabric Heat Transfer Printing

A good heat press is the key to getting great results in fabric printing. Quality equipment can make your work much faster and better, with features like temperature control and pressure settings helping you handle different types of cloth. Digital displays make it super easy to get the right settings every time.

Selecting the Right Papers and Inks

You need to pick the right transfer paper that works with your printer. The paper you choose should match what you’re printing on – light paper for white clothes and dark paper for dark clothes. Get a printer that’s known to be good at printing colors that last.

Making sure your prints last a long time means picking good materials.

When you use the right tools and materials together, you’ll get great results. This helps you make bright, long-lasting designs without wasting time or materials.

Conclusion

Heat transfer printing is a mix of art and skill that can make your fabric designs look great. Creating amazing prints requires careful attention to heat levels, pressure settings, and the right methods for each project, and these basics are key for anyone looking to get started in this field.

Every technique – from sublimation to DTF and vinyl transfers – has its special uses. You’ll need quality tools to get the best results, like good heat presses and transfer papers that won’t let you down. Through my years of work in this field, I’ve seen how big a difference the right setup makes.

Making great prints means keeping up with new ideas and fixes for common problems. Sometimes you’ll face tricky issues, but that’s part of getting better at what you do. The more you practice and try new things, the better your prints will turn out.

FAQ:

- Q: What temperature is best for heat transfer printing on fabric?

A: The optimal temperature range is typically 350°F-375°F, but it may vary depending on the fabric type and transfer method used. - Q: How long do heat transfer prints last on fabric?

A: With proper application and care, heat transfer prints can last through many washes while maintaining their color and clarity. - Q: What types of fabric work best for heat transfer printing?

A: Most fabrics work well, but polyester is ideal for dye sublimation, while cotton works great with traditional heat transfer methods. - Q: Do I need special paper for dark fabrics?

A: Yes, dark fabrics require specific transfer paper designed for dark materials to ensure proper color visibility and adhesion. - Q: What’s the difference between DTF and dye sublimation printing?

A: DTF uses special glue and powder to adhere to any fabric color, while dye sublimation turns ink into gas and works best on synthetic fabrics like polyester.