Introduction

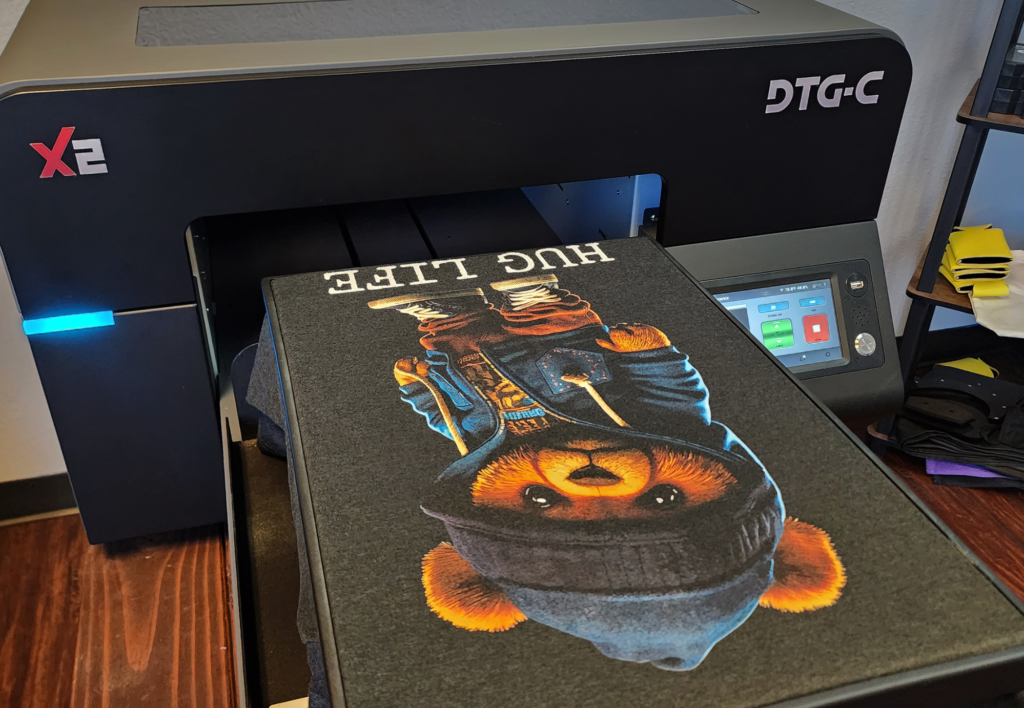

Direct-to-garment (DTG) printing is changing how we make custom clothes. This groundbreaking method uses special printers to put designs right onto fabrics, and the results are truly remarkable for anyone looking to create unique clothing items.

The setup is quick. Digital files go straight from computer to fabric through advanced printers that work much like the ones we use at home, though these are built specifically for clothing.

Getting started is simple. These printers can create detailed images on cotton and similar materials with stunning clarity, making them perfect for small batches of custom shirts or other items.

How It Works

The process is earth-friendly. Water-based inks mean less harm to our planet, which is why more businesses are choosing DTG printing over older methods.

This guide shows you everything about DTG printing. Whether you’re just learning or running a small business, we’ll cover what it is, how it works, and what makes it great or not so great for different projects.

What is DTG Fabric Printing?

Direct-to-garment (DTG) fabric printing puts ink right onto clothes using digital technology. The specialized printer carefully drops water-based ink onto the fabric in a process that’s safe for the environment and creates sharp, colorful designs.

The Printing Process

The first step is getting the design file ready on a computer. A special coating gets sprayed on the garment to help the ink stick better, which is really important for making the print look good.

After the coating dries, the printer starts laying down ink on the fabric just like a regular printer does with paper. The ink soaks into the fabric instead of sitting on top, which makes the design feel soft when you touch it and lets it show all kinds of colors and details really well.

DTG works best on cotton clothes or clothes that are mostly cotton. Light-colored polyester can work too if it’s treated right first. This makes DTG perfect for making small amounts of custom shirts or other clothes.

DTG Fabric Printing Advantages

Why Choose DTG?

DTG printing makes clear, colorful designs on fabric. The computer-controlled process creates pictures that look almost like photos in amazing detail.

The ink used in DTG is safe for the environment. This method creates very little waste and doesn’t release many harmful chemicals into the air.

You can start printing right away with DTG. The simple process means you can make just one shirt or many shirts quickly without losing any quality in the prints. This makes it perfect for small orders.

DTG works great with many types of designs and colors. The printing feels soft on the fabric and lasts a long time, especially on cotton shirts.

DTG saves money because it wastes very little material. This way of printing lets you make exactly what you need, when you need it. Companies are choosing DTG more and more because it just makes sense.

Limitations of DTG Fabric Printing

DTG fabric printing works best on cotton and similar natural materials. The process faces significant challenges when printing on dark-colored garments, as it requires a white underbase layer that can affect the final design quality and use more ink.

Production Issues

DTG printing is perfect for small orders. However, when it comes to large-scale production, the process is much slower and needs more maintenance than traditional screen printing, making it less practical for big orders .

The printer uses special water-based inks that work well with cotton. These same inks don’t perform as effectively on synthetic fabrics like polyester or blended materials, which limits what you can print on.

Applications of DTG Fabric Printing

DTG fabric printing has changed how custom clothes are made. Boutique brands and small shops can now print detailed designs on t-shirts and hoodies with amazing quality. On-demand printing has become easier than ever, letting businesses make just what they need.

Business Benefits

Small businesses love DTG printing. The process helps companies make branded clothes and special designs without spending too much money up front, which is great for their budgets.

Artists can now print their work directly onto fabric with stunning detail. DTG lets them create limited-edition items and custom pieces while being kind to the environment, which is a short but powerful selling point.

The technology now reaches beyond just clothing into home decoration. According to Aesthetic BK’s comprehensive guide, people can get custom tote bags, pillows, and wall art with bright, clear prints that look amazing.

Conclusion

DTG fabric printing gives you high-quality designs straight on clothes. This revolutionary process has brought many benefits to the world of custom garment production, including less waste and the ability to make small batches whenever they’re needed.

The process is simple to set up. DTG printing technology allows businesses to create incredibly detailed and colorful designs with amazing accuracy, making it perfect for both basic and complex artwork.

FAQ

- What is DTG printing and how does it work?

- DTG (Direct-to-Garment) printing is a digital printing method that applies water-based ink directly onto fabric using specialized printers, similar to regular inkjet printing but designed for textiles.

- What materials work best with DTG printing?

- DTG printing works best on 100% cotton or cotton-blend fabrics, with light-colored garments providing the best results. Some treated polyester materials can also work.

- How does DTG printing compare to screen printing?

- DTG printing is ideal for small orders and detailed designs but slower for large quantities, while screen printing is more cost-effective for bulk orders but requires more setup time.

- Is DTG printing environmentally friendly?

- Yes, DTG printing is eco-friendly as it uses water-based inks, creates minimal waste, and produces fewer harmful emissions compared to traditional printing methods.

- How long do DTG printed designs last?

- DTG printed designs can last for many washes when properly cared for, though durability may vary depending on the fabric type and washing conditions.